Common causes of failure of combined punching and shearing machines

Release Time:

Sep 02,2024

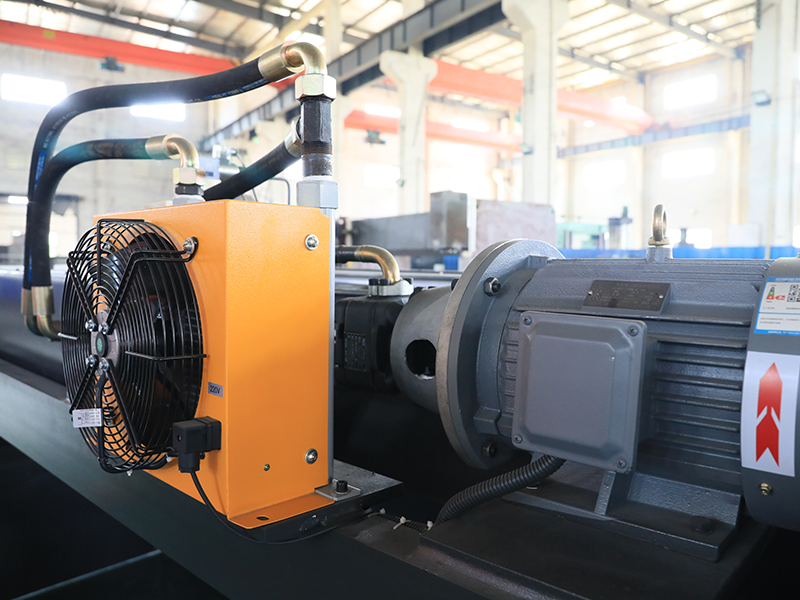

The combined punching and shearing machine is a mechanical device that combines the functions of metal cutting, punching, shearing, and sheet metal bending. It has the advantages of simple operation, low energy consumption, and low maintenance.

The combined punching and shearing machine is a mechanical device that combines the functions of metal cutting, punching, shearing, and sheet metal bending. It has the advantages of simple operation, low energy consumption, and low maintenance. It is Laser cutting and processing machinery and equipment for metal materials in intelligent processing industries (such as metallurgical industry, roads and bridges, communications, power engineering, military and other manufacturing industries). Combined punching and shearing machines are divided into two types: hydraulic press combined punching and shearing machines and mechanical equipment combined punching and shearing machines.

Then when people use the combined punching and shearing machine, they will encounter some common faults, such as difficulty in threading materials and clutch slipping. So how should we deal with it? Let's take a look at it with the net editor.

What will happen and how to solve it

1. The forming deformation of the frame material is too large. The forming machine can be adjusted to correct the poor forming.

2. If the seams of the moving knife and fixed cutlery and cutlery are not pointed, you can use a flashlight to adjust the direction of the moving knife.

3. The viewing angle error of the material feeding platform can be adjusted.

Cut the continuous material

1. If the hydraulic cylinder pressure is not enough, it can be adjusted to normal pressure: 12-16 MPa

2. The blade laminating machine is too loose and the blade is loose. You can tighten the adjusting screw and fixing screw.

3. If there is dirt between the two cutter heads, you can remove the movable cutter head without suturing, clean it and install it tightly.

5. If the wound is damaged or there is no spark discharge, it can be disassembled for inspection and planned repair.

5. The knife schedule is insufficient and the schedule time can be adjusted.

The clutch of the combined punching and shearing machine is slipping and the braking system is loose.

Solution:

To clean, you can adjust the cover and nut or replace the conical friction cone. Adjust the braking torque, tighten the brake belt, and tighten the brake wheel.

(1) Full load and rapid operation to remove gas

(2) Tighten the seal and drip oil to the mark on the oil level gauge

(3) Adjust the hydraulic cylinder clearance control to 0.02-0.05mm

(4) Oil dripping lubrication

(5) Adjust the working pressure of the oil

(6) Clean the filter.

Online Inquiry

We will contact you within one working day. Please pay attention to your email.